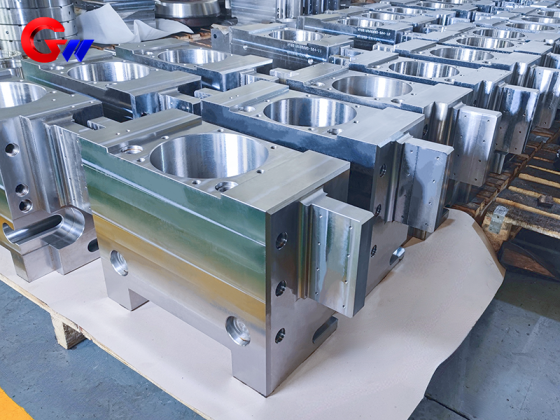

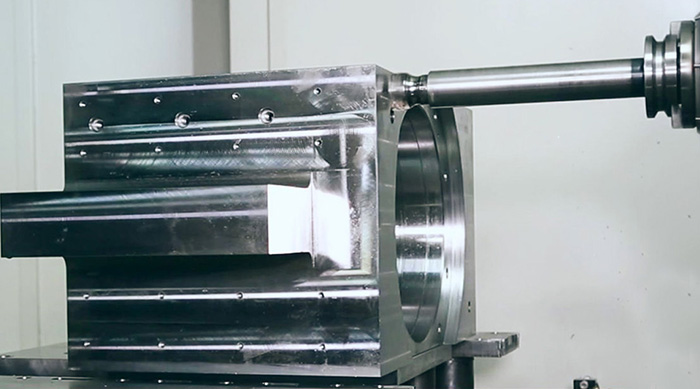

Valsemøllelagerblokk av støtterull av kaldmøllemaskin

Bruksscenarioer for valselagerseter for støttevalser for kalde valseverk

1. Kjernefunksjoner

Støtteplassering: Fest støtterullene nøyaktig, motstå rullekrefter på opptil tusenvis av tonn og spre dem til rammen.

Kraftoverføring: Rulletrykket overføres til det hydrauliske pressesystemet gjennom lagre for å oppnå justering av rullegapet.

Dynamisk stabilitet: Undertrykk rullevibrasjoner (som harmoniske forårsaket av stripeavvik eller tykkelsessvingninger).

2. Typiske bruksmodeller

Multivals kaldvalseverk: som Sendzimir 20 valseverk, fire-/seksvals kaldvalseverk (brukes til høypresisjonsbåndstål som rustfritt stål og silisiumstål).

Presisjonsvalselinje: et ultratynt båndvalseverk med et tykkelseskontrollnøyaktighetskrav på ≤ 1 μm.

- GW Precision

- Luoyang, Kina

- Kontraktsbestemmelse

- Årlig kapasitet er 500 stk

- informasjon

Rolling Mill Bearing Block Of Supporting Roller Of Cold Mill Machine

Performance characteristics of Rolling Mill Bearing Seat

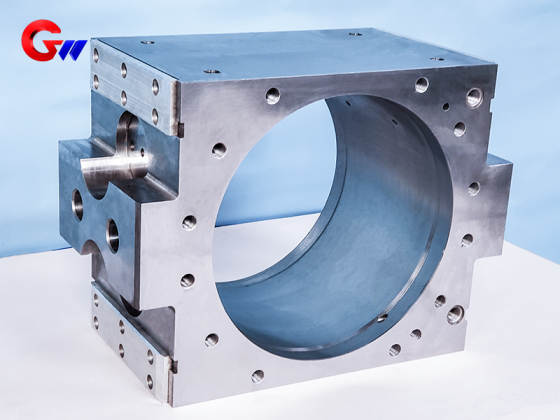

1. Material and structural design

texture of material:

Cast steel (ZG35CrMoV): Strong fatigue resistance and moderate cost (mainstream choice).

Forged steel (42CrMo4): used for ultra heavy rolling mills, with a 20% increase in load-bearing capacity.

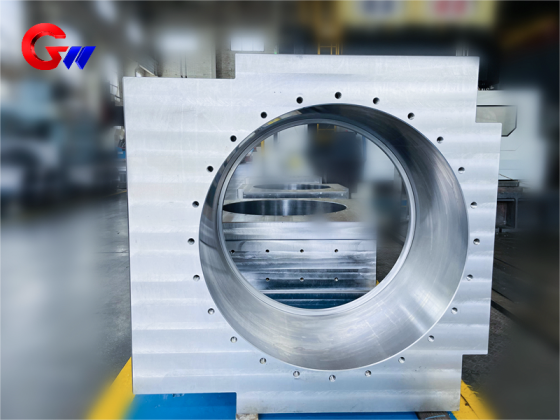

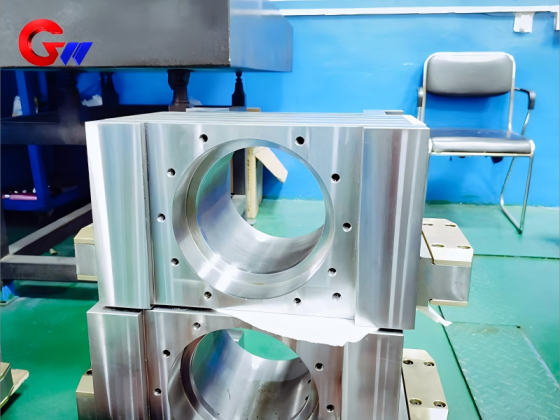

Structure:

Split box: The upper and lower halves of the box are pre tightened with hydraulic bolts (pre tightening force ≥ 1.5 times the working load).

Built in sensor slot: can integrate pressure sensors (measuring bearing load) and temperature probes.

2. Key performance parameters

Typical values of indicators/required testing conditions

Static bearing capacity 2000-5000 kN (single-sided) maximum rolling force condition

Dynamic stiffness ≥ 500 kN/μ m (axial) exciter frequency response test

Bearing temperature rise control ≤ 45 ° C (oil film bearing working condition) infrared thermal imaging monitoring

Sealing cleanliness NAS 1638 Class 6 (lubricating oil) particle counter detection

3. Special design features

Hydraulic labyrinth seal: an air seal with a pressure of 0.05-0.1MPa and multiple rubber lip seals to prevent emulsion from entering.

Quick roller changing system: The bottom of rolling mill bearing seat is integrated with a hydraulic lifting guide rail, and the roller changing time is ≤ 30 minutes.

Micron level alignment: using a wedge adjustment mechanism, the horizontal/vertical alignment accuracy is ≤ 0.01mm.

Key parameters for the production and manufacturing of hot rolling rolls

Chemical composition (taking high chromium cast iron as an example):

C: 2.5~3.5%, Cr: 12~20%, Mo: 1~3%, Ni: 0.5~1.5%, V: 0.5~1.5%。

Heat treatment process:

Quenching: Oil quenching or air cooling at 950~1050 ℃ to increase hardness.

Tempering: 400~550 ℃ to relieve stress and balance toughness and hardness.

Cryogenic treatment (optional): -70~-196 ℃ to enhance residual austenite transformation.

Mechanical properties:

Hardness: The surface hardness of the finishing roll is ≥ 70 HS (Shore hardness), and the surface hardness of the roughing roll is ≥ 55 HS.

Tensile strength: ≥ 800 MPa (forged steel rollers can reach over 1200 MPa).

Impact toughness: ≥ 15 J/cm ² (core requirement).

Manufacturing process for rolling mill bearing seat:

Casting: Centrifugal casting is used for composite rollers (outer wear-resistant material+core tough material).

Forging: Steel rollers require multi-directional forging to refine grain size.

Processing accuracy: roller diameter tolerance ± 0.05mm, roughness Ra ≤ 0.8 μ m.

Cooling and lubrication:

Internal water cooling of the rolling mill (water temperature 20-40 ℃, flow rate ≥ 5m/s).

Rolling lubrication uses graphite or synthetic lubricants to reduce steel sticking.

I produksjonsprosessen for valsebærende setebøyingsrulleblokk og andre produkter, blir det optimaliserte prosesseringsprogrammet kompilert av datamaskinen, og prosessplanen er ordnet rimelig, noe som sikrer at valsemøllelagerets setekvalitet når den internasjonale førsteklasses standarden.